The increasing requirements on industrial automation and energy conservation continues to promote the development of variable-frequency drive (VFD) and its widespread applications in electric power, cement, elevator, mining, metallurgy, transportation and other sectors. Over the past few years, the VFD market has seen rapid growth. In recent years, in particular, the VFD market has maintained an annual growth rate of 12%-15%, expected to continue growing at a rate of more than 10% within five years.

News

ARTERY AT32 MCU Vector Variable-Frequency Drive Solution for Industrial Automation

As a power control device, the VFD is used to control Alternating Current Motor (AC motor) by changing the operating frequency of the motor with the help of frequency conversion technology and microelectronic technology.

In the process of VFD operation, the MCU, as a critical component in VFD system, provides power supply required for the motor. Along with the development of high performance microprocessors and modern control technology, the variable-frequency drive is increasingly becoming small and lightweight, and moving toward high performance, high function and environment-friendly development.

Vector variable-frequency drive (VVFD) & Variable-frequency drive (VFD)

In general, the frequency converter contains general-purpose frequency converter ad vector frequency converter.The VVFD is similar to DC motor in terms of control logic. It uses the vector control technology and is based on dynamic mathematic model of the rotor flux oriented control which is commonly used in the field of asynchronous motor.

As for the working machines like industrial robots with fast response requirements, the driving system needs to be responsive at a speed of at least 100rad/s. As the VVFD can be up to 1000rad/s, it is capable of enabling the robot driving system to work fast and accurately. Because of this, the VVFD is often used in the scenario of heavy starting duty such as high-power conveyor belts and hoist. But this is not the case for common frequency converter. The heavy load and insufficient torque induced during startup would cause the motor to fail to start, resulting in blocked error or overcurrent.

ARTERY AT32 MCU VFD application

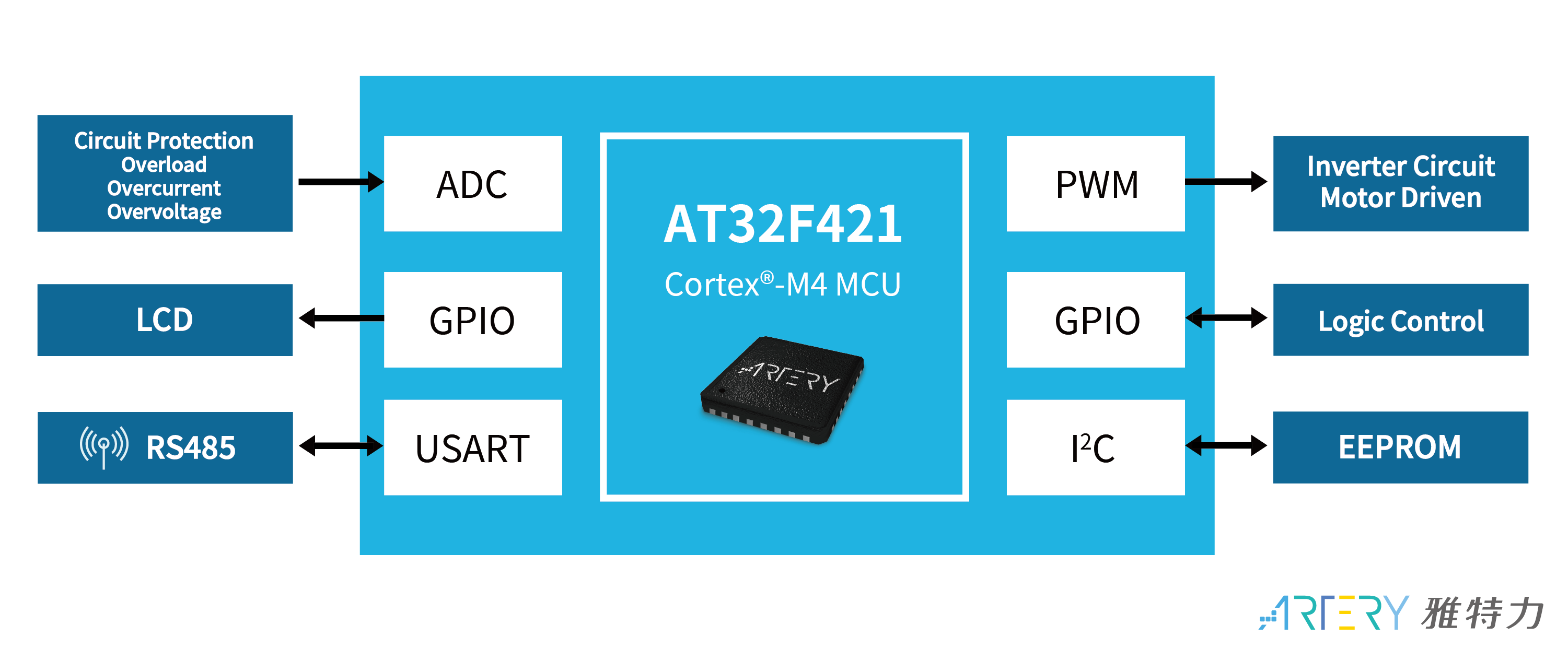

The vector frequency control provides large and stable output torque, low noise and high efficiency. However, it deals with complex algorithm and a large amount of computation, thus putting forward higher requirements for the performance of MCUs. In this respect, ARTERY value line AT32F421 series based on ARM® Cortex®-M4 core gives a cost-effective solution to the VVFD application. The AT32F421 series operates at a frequency of up to 120 MHz, and embeds up to 64KB Flash memory and 16 KB SRAM, with rich interfaces and many features, thereby ensuring high performance and precision of motor drive control system. And last but not least, its price is nearly close to M0-powered MCU in price even though it is powered by M4 core.

The core part of the VVFD system is the AT32F421C8T7 MCU, which controls the IGBT and current sensor in VVFD for energy saving, speed regulation and VVFD protection against overcurrent, overvoltage and overload. The AT32F421 series features fast GPIO response and ADC conversion rate of up to 2MHz, thus ensuring high-speed VVFD response, precise control of torque, flexible speed adjustment and good acceleration and deceleration control. All this makes it particularly suitable to the applications with high torque control requirements.

On the other hand, the VVFD must maintain stability in the industrial environment challenged by electromagnetic waves, corrosion gases and vibration, etc. The AT32F421 series works in the temperature range of -40 to 105°C and is therefore able to withstand the severe environment, for instance, paper machines, printing and dyeing machines need to operate in high-humid, high-temperature environments corrosive gases.

AT32F421C8T7 application advantages

● Cortex®-M4 core, cost-effective, up to 120MHz max frequency, fast computing power

● Rich peripheral interfaces, flexible data acquisition, supporting interconnection with multiple terminal devices

● Fast GPIO response and ADC conversion rate up to 2MHz

● Able to work in the wider temperature range of -40 to 105°C

Sales Contacts

News Contacts

About Artery

ARTERY Technology 雅特力科技 is a professional creator and maker of 32-bit MCU founded in 2016, with branch offices in Chongqing, Shenzhen, Suzhou and Taiwan specialized in R&D, sales and technical service support. Since 2008, tens of millions of products have been put on the market and widely used in various fields covering 5G, IoT, consumer, business and industrial control, such as, micro printer, balance wheeler, three-axis handheld stabilizer, electronic whiteboard, fingerprint recognition, sweeping robot, optical flow drone, electric vehicle controllers, scooter and panel, stage lighting, thermal imager, LED advertising display, wall switches, INS, DVR, robot control and other terminal applications.Thanks to the popularity of IoT and smart manufacturing, Artery will continue to place emphasis on the development of MCUs, and partner with 21ic, Chuangyizhan, Sekorm and other third-party platforms in response to the increasing demand of intelligent hardware, more importantly, to make a positive contribution to the building of the world-class industrial ecosystem!